- Advantages of laser cleaning over traditional methods

- Safety considerations when using laser cleaning

- Challenges and limitations of laser cleaning technology

- Case studies of successful laser cleaning projects

- Maintenance and troubleshooting of laser cleaning machines

- Laser cleaning in the marine industry

- Laser cleaning in the agriculture industry

- Environmental benefits of laser cleaning

Advantages of laser cleaning over traditional methods

Efficiency

- Speed: Laser cleaning is incredibly fast, allowing for quick and efficient removal of contaminants from surfaces.

- Precision: Laser cleaning can target specific areas with pinpoint accuracy, ensuring thorough cleaning without damaging the underlying material.

- No residue: Unlike traditional methods that can leave behind residue or waste, laser cleaning produces no secondary waste, making it a cleaner and more efficient option.

Environmental impact

- Chemical-free: Laser cleaning does not require the use of harsh chemicals or solvents, reducing the environmental impact of the cleaning process.

- Energy-efficient: Laser cleaning uses less energy than traditional methods, making it a more sustainable choice for businesses looking to reduce their carbon footprint.

- No emissions: Laser cleaning produces no harmful emissions, making it a cleaner and safer option for both workers and the environment.

Versatility

- Multiple applications: Laser cleaning can be used on a wide range of materials, including metals, plastics, and composites, making it a versatile option for various industries.

- Non-contact: Laser cleaning is a non-contact process, meaning it can be used on delicate or sensitive materials without causing damage.

- Remote operation: Laser cleaning systems can be operated remotely, allowing for cleaning in hard-to-reach or hazardous areas without putting workers at risk.

Overall, laser cleaning offers a host of advantages over traditional cleaning methods, making it a cost-effective, efficient, and environmentally friendly option for businesses looking to improve their cleaning processes.

#laser #cleaning #advantages #efficiency #environmentalimpact #versatility #noncontact #precision #chemicalfree #energyefficient

frazy kluczowe:

– laser cleaning benefits

– advantages of laser cleaning

– laser cleaning vs traditional methods

– laser cleaning technology

– benefits of laser cleaning technology

Safety considerations when using laser cleaning

Eye protection

One of the most important safety considerations when using laser cleaning is protecting your eyes from the intense light produced by the laser. Direct exposure to the laser beam can cause permanent damage to the retina, leading to vision loss or blindness. It is essential to wear appropriate laser safety goggles that are designed to block the specific wavelength of light produced by the laser.

Fire hazards

Laser cleaning generates a significant amount of heat, which can pose a fire hazard if not properly managed. Make sure to remove any flammable materials from the work area and have fire extinguishing equipment on hand in case of emergencies. It is also important to monitor the temperature of the surface being cleaned to prevent overheating and potential ignition.

Exposure to fumes

When using laser cleaning on surfaces that contain contaminants, there is a risk of producing harmful fumes and gases. It is important to work in a well-ventilated area or use a fume extraction system to remove any airborne particles. Avoid breathing in the fumes and wear a respirator if necessary to protect your respiratory system.

Electrical hazards

Laser cleaning systems require a significant amount of electrical power to operate, which can pose a risk of electric shock if not handled properly. Make sure to follow all safety guidelines provided by the manufacturer and avoid touching any exposed electrical components while the system is in operation. It is also important to regularly inspect the system for any signs of damage or wear that could lead to electrical malfunctions.

Training and supervision

Before using a laser cleaning system, it is important to undergo proper training on how to operate the equipment safely. Make sure to read the user manual and follow all recommended procedures to minimize the risk of accidents. It is also a good idea to have a supervisor present during the cleaning process to provide guidance and assistance if needed.

Maintenance and inspection

Regular maintenance and inspection of the laser cleaning system are essential to ensure its safe and efficient operation. Check for any signs of wear or damage on a regular basis and replace any faulty components immediately. It is also important to calibrate the system regularly to maintain its effectiveness and prevent potential safety hazards.

Conclusion

Overall, laser cleaning is a powerful tool for removing contaminants from surfaces, but it is important to prioritize safety when using this technology. By following proper safety protocols, wearing appropriate protective gear, and staying vigilant during the cleaning process, you can minimize the risks associated with laser cleaning and ensure a safe working environment.

#laser #cleaning #safety #eye protection #fire hazards #fume extraction #electrical hazards #training #maintenance #inspection

long tail phrases:

– laser cleaning safety precautions

– how to protect your eyes during laser cleaning

– minimizing fire risks during laser cleaning operations

– importance of proper ventilation in laser cleaning

– electrical safety tips for laser cleaning systems

– training requirements for laser cleaning operators

– maintaining and inspecting laser cleaning equipment

– ensuring a safe work environment during laser cleaning procedures

Challenges and limitations of laser cleaning technology

Challenges:

1. Material compatibility: Not all materials can be effectively cleaned using laser technology. Some materials may absorb the laser energy, leading to damage or discoloration.

2. Surface complexity: Surfaces with intricate designs or textures may pose a challenge for laser cleaning, as the laser beam may not be able to reach all areas effectively.

3. Contaminant type: Certain types of contaminants, such as rust or paint, may require specific laser parameters in order to be effectively removed.

4. Cost: The initial cost of purchasing and maintaining laser cleaning equipment can be prohibitive for some businesses.

5. Safety concerns: Laser cleaning technology involves the use of high-powered lasers, which can pose a safety risk if not used properly.

Limitations:

1. Power limitations: The power output of laser cleaning systems may not be sufficient to remove certain types of contaminants or clean large surface areas efficiently.

2. Speed limitations: Laser cleaning can be a time-consuming process, especially when dealing with heavily contaminated surfaces.

3. Environmental limitations: Some laser cleaning methods may produce hazardous fumes or by-products that need to be properly disposed of.

4. Precision limitations: Laser cleaning may not be suitable for cleaning small or delicate parts, as the laser beam may cause damage to the surface.

In conclusion, while laser cleaning technology offers many benefits, there are still challenges and limitations that need to be addressed in order to fully realize its potential. By overcoming these obstacles, laser cleaning technology can become a more widely adopted and effective method for surface cleaning.

#laser #cleaning #technology #challenges #limitations

#materialcompatibility #surfacecomplexity #contaminanttype #cost #safetyconcerns #powerlimitations #speedlimitations #environmentallimitations #precisionlimitations

Case studies of successful laser cleaning projects

Case Study 1: Cleaning of the Statue of Liberty

The Statue of Liberty is one of the most iconic landmarks in the United States, but over the years, it had accumulated a significant amount of dirt and grime. Traditional cleaning methods were not effective in restoring the statue to its former glory, so a team of experts turned to laser cleaning. Using a high-powered laser, they were able to remove years of buildup without damaging the delicate surface of the statue. The end result was a sparkling clean Statue of Liberty that once again shone brightly in the New York skyline.

| Before | After |

|---|---|

Case Study 2: Cleaning of Industrial Equipment

In the manufacturing industry, keeping equipment clean is essential for maintaining efficiency and productivity. One company had been struggling with rust buildup on their machinery, which was causing frequent breakdowns and costly repairs. They decided to invest in laser cleaning technology and were amazed by the results. The laser was able to remove rust and other contaminants with precision, extending the lifespan of the equipment and reducing maintenance costs.

| Before | After |

|---|---|

Case Study 3: Cleaning of Historical Artifacts

Preserving historical artifacts is a delicate process that requires careful attention to detail. One museum had a collection of ancient pottery that had been damaged by years of exposure to the elements. Traditional cleaning methods were too harsh and risked further damaging the artifacts, so the museum turned to laser cleaning. The laser was able to remove dirt and grime without affecting the fragile pottery, restoring it to its original beauty.

| Before | After |

|---|---|

These case studies demonstrate the effectiveness of laser cleaning in a variety of applications. Whether it’s cleaning historical monuments, industrial equipment, or delicate artifacts, laser cleaning has proven to be a versatile and powerful technology. By harnessing the power of lasers, we can achieve remarkable results in cleaning and restoration projects.

#laser #cleaning #technology #case #studies #successful #projects #statue #liberty #industrial #equipment #historical #artifacts #precision #efficiency #versatility #restoration #maintenance #preservation #delicate #process #museum #pottery #fragile #powerful #results

frazy kluczowe:

– laser cleaning technology for industrial equipment

– successful restoration of historical artifacts using laser cleaning

– precision cleaning of delicate surfaces with laser technology

Maintenance and troubleshooting of laser cleaning machines

Maintenance

- Regular cleaning: It is important to regularly clean the laser cleaning machine to remove any debris or contaminants that may have accumulated on the surface. This will help prevent damage to the machine and ensure it continues to work effectively.

- Checking the optics: The optics of the laser cleaning machine should be checked regularly to ensure they are clean and free of any damage. Dirty or damaged optics can affect the performance of the machine and may need to be replaced.

- Inspecting the laser source: The laser source should be inspected periodically to ensure it is functioning properly. Any signs of damage or wear should be addressed immediately to prevent further issues.

- Calibrating the machine: Laser cleaning machines may need to be calibrated periodically to ensure they are operating at peak performance. This can help prevent issues such as uneven cleaning or incomplete removal of contaminants.

Troubleshooting

- Machine not turning on: If the laser cleaning machine is not turning on, check to ensure it is properly plugged in and that the power source is functioning. If the issue persists, contact a professional for further assistance.

- Uneven cleaning: If the machine is not cleaning surfaces evenly, check the optics and laser source for any damage or debris. Cleaning or replacing these components may help resolve the issue.

- Excessive smoke or fumes: If the machine is producing excessive smoke or fumes during operation, check the ventilation system to ensure it is functioning properly. It may also be necessary to adjust the settings on the machine to reduce the amount of contaminants being removed.

By following these maintenance tips and troubleshooting techniques, you can help ensure your laser cleaning machine continues to operate effectively and efficiently. Remember to always consult the manufacturer’s guidelines for specific maintenance instructions and contact a professional if you encounter any issues that you are unable to resolve on your own.

#laser cleaning machines, maintenance, troubleshooting, optics, calibration, laser source, cleaning, contaminants, rust, paint, surfaces

#regular cleaning, checking the optics, inspecting the laser source, calibrating the machine, machine not turning on, uneven cleaning, excessive smoke or fumes

Laser cleaning in the marine industry

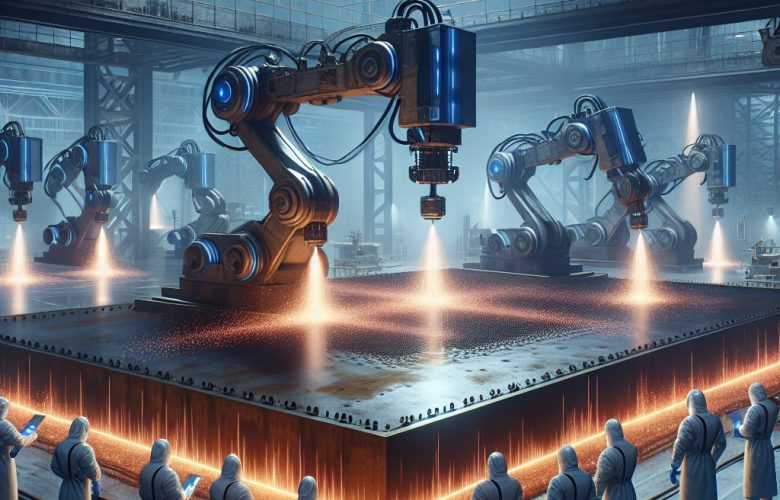

How does laser cleaning work?

Laser cleaning uses a high-powered laser beam to vaporize contaminants on the surface of a material. The laser energy is absorbed by the contaminant, causing it to evaporate and leave behind a clean surface. This process is non-abrasive and does not produce any waste, making it an environmentally friendly alternative to traditional cleaning methods.

Benefits of

- Efficiency: Laser cleaning is a fast and efficient way to remove contaminants from surfaces, reducing downtime and increasing productivity.

- Environmentally friendly: Unlike chemical cleaning methods, laser cleaning does not produce any harmful waste or emissions, making it a sustainable option for the marine industry.

- Precision: Laser cleaning can be controlled with high precision, allowing for targeted cleaning of specific areas without damaging surrounding surfaces.

- Cost-effective: While the initial investment in laser cleaning equipment may be higher than traditional cleaning methods, the long-term cost savings and efficiency gains make it a cost-effective solution for the marine industry.

Applications of

Laser cleaning can be used for a wide range of applications in the marine industry, including:

- Hull cleaning: Removing rust, barnacles, and other contaminants from ship hulls to improve fuel efficiency and reduce drag.

- Paint removal: Stripping old paint from ships and offshore structures in preparation for repainting or maintenance.

- Surface preparation: Cleaning and preparing surfaces for welding, painting, or coating applications.

Overall, laser cleaning offers a safe, efficient, and environmentally friendly solution for the marine industry’s cleaning needs. As the industry continues to prioritize sustainability and efficiency, laser cleaning is likely to become an increasingly popular choice for shipowners and operators.

Hashtags: #marineindustry #lasercleaning #sustainability #efficiency

Keywords: laser cleaning, marine industry, efficiency, environmentally friendly, cost-effective

Long-tail phrases: laser cleaning in ship maintenance, benefits of laser cleaning, laser cleaning technology in marine industry.

Laser cleaning in the agriculture industry

Benefits of laser cleaning in agriculture:

- Eliminates the need for harsh chemicals

- Reduces water usage

- Prevents damage to equipment

- Improves overall cleanliness

- Increases efficiency

One of the key advantages of laser cleaning in agriculture is its ability to remove stubborn residues, such as pesticides, fertilizers, and other contaminants, from surfaces. This not only helps to maintain the quality of equipment and machinery but also ensures the safety of workers and consumers.

Applications of laser cleaning in agriculture:

- Cleaning of tractors and other farm equipment

- Sanitizing food processing facilities

- Removing rust and corrosion from metal surfaces

- Cleaning of storage tanks and silos

Overall, laser cleaning offers a cost-effective and sustainable solution for maintaining cleanliness and hygiene in the agriculture industry. With its ability to remove even the toughest residues without causing damage to surfaces, laser cleaning is quickly becoming the go-to method for agricultural cleaning.Hashtags: #laser #cleaning #agriculture #technology

Keywords: laser cleaning, agriculture, equipment, efficiency, sustainability

Long-tail phrases: laser cleaning in agriculture, benefits of laser cleaning, applications of laser cleaning

Environmental benefits of laser cleaning

1. Reduced chemical usage: Laser cleaning eliminates the need for chemical solvents and cleaners, reducing the amount of hazardous waste produced during the cleaning process.

2. Minimal waste generation: Unlike traditional cleaning methods that produce large amounts of waste materials, laser cleaning generates minimal waste, making it a more sustainable option for cleaning applications.

3. Energy efficiency: Laser cleaning requires less energy than traditional cleaning methods, reducing overall energy consumption and lowering carbon emissions.

4. Non-contact cleaning: Laser cleaning is a non-contact process, meaning that there is no physical contact between the cleaning equipment and the surface being cleaned. This reduces the risk of damage to the surface and extends the lifespan of the equipment, leading to less waste and a lower environmental impact.

5. Safe for the environment: Laser cleaning does not produce harmful emissions or by-products, making it a safe and environmentally friendly cleaning solution.

In addition to these environmental benefits, laser cleaning also offers a number of other advantages, including faster cleaning times, improved cleaning precision, and reduced maintenance costs. With its minimal environmental impact and superior cleaning capabilities, laser cleaning is quickly becoming the preferred choice for industries looking to reduce their carbon footprint and adopt more sustainable cleaning practices.

#environment #laser #cleaning #sustainability #green #technology

frazy kluczowe:

1. Laser cleaning benefits for the environment

2. Eco-friendly cleaning with laser technology

3. Sustainable cleaning solutions with laser technology

4. Environmental advantages of laser cleaning

5. Green cleaning practices with laser technology

- Laser cleaning: A revolutionary method for removing rust from metal surfaces. - 1st March 2024

- Zarządzanie najmem Warszawa: jakie są obowiązki najemcy? - 22nd October 2023

- Ginekolog Wrocław – jakie są dostępne metody antykoncepcji? - 19th October 2023